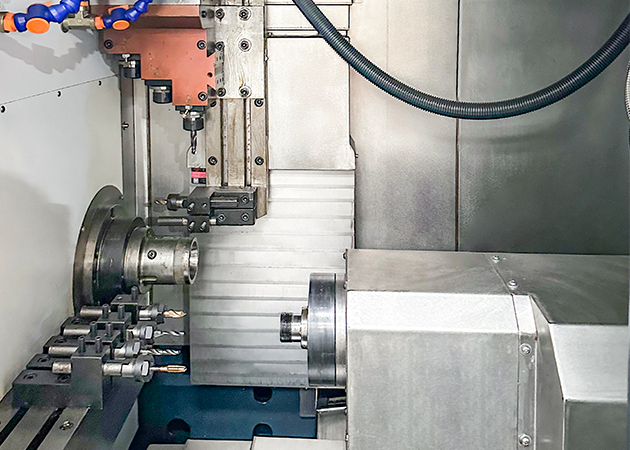

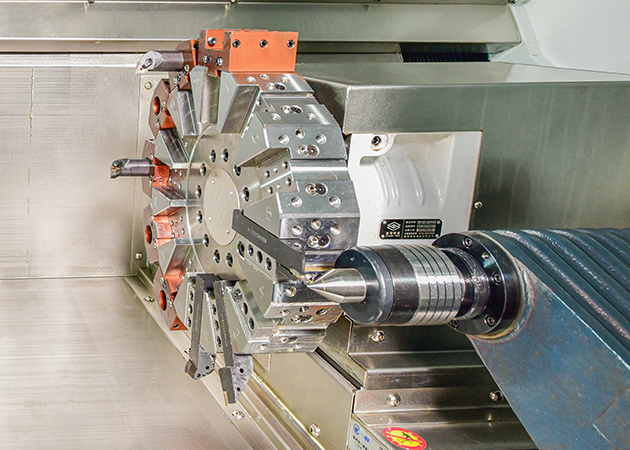

Five-axis linkage vs. three-axis: What can the two additional axes do?

CK46A Linear Guide Rail CNC Slant Bed Lathe-

CK46A Linear Guide Rail CNC Slant Bed Lathe

1. X/Z axis reach 900/300mm 2. 46mm Spindle 3. 425mm Maximum Rotation Diameter Features a. The integrated base design and 35° inclined bed enhance the rigidity of the lathe machine, ensuring the CNC lathe machine delivers superior stability and p...

CK36 Linear Guide Rail CNC Slant Bed Lathe-

CK36 Linear Guide Rail CNC Slant Bed Lathe

1. Casting Base 2. 36mm Spindle 3. 400mm Maximum Rotation Diameter Features Features a. The machine features a 35° inclined casting base, enhancing rigidity and stability for the CNC lathe machine. This robust casting base ensures the cnc lathe oper...

STDS52-46 Single Turret Dual Spindles CNC Slant Bed Lathe-

STDS52-46 Single Turret Dual Spindles CNC Slant Bed Lathe

1. Dual spindles (Main/Sub - 52/46mm) 2. Maximum processing diameter*length up to 360*550mm Features a. The CNC lathe machine (bed base, bed frame and headstock) features a durable casting base, bed frame, and headstock crafted from high-strength ma...

DS46-36 Dual Spindles Gang Type CNC Slant Bed Lathe-

DS46-36 Dual Spindles Gang Type CNC Slant Bed Lathe

1. Dual spindles (Main/Sub - 46/36mm) 2. Maximum cutting length up to 220mm Features a. The CNC lathe machine features a durable casting base, bed frame, and headstock crafted from high-strength materials, ensuring exceptional stability b. Dual s...

CK(46)52ST Servo Turret Tailstock CNC Slant Bed Lathe-

CK(46)52ST Servo Turret Tailstock CNC Slant Bed Lathe

1. Oil pressure programmable tailstock 2. Disc type processing diameter up to (400) 500mm Features a. CNC lathe machine features an integrated design with a robust casting base and a 35° inclined bed, enhancing overall rigidity. Optimized through ...

CK(46)52PT-Y Power Turret Tailstock CNC Slant Bed Lathe-

CK(46)52PT-Y Power Turret Tailstock CNC Slant Bed Lathe

1. Oil pressure programmable tailstock 2. Y-axis power turret Features a. The CNC lathe machine features an integrated design with a robust casting base and a 35° inclined bed, enhancing overall rigidity. b. Equipped with a high-precision rigid spind...

CK46B Y4+4 Turning and milling CNC Slant Bed Lathe -

CK46B Y4+4 Turning and milling CNC Slant Bed Lathe

1. Casting base 2. Maximum stroke of Y-axis up to 210mm 3. Maximum machining length reach to 280mm Features a. The CK46B Y4+4 CNC lathe machine features an HT300 one-piece casting base, ensuring durability with secondary tempering for small and med...

DTDS46-36 Dual Turret Dual Spindles CNC Slant Bed Lathe-

DTDS46-36 Dual Turret Dual Spindles CNC Slant Bed Lathe

1. Dual spindles (Main/Sub - 46/36mm) 2. Maximum rotation diameter on the bed up to 500mm Features a. The CNC lathe machine features a durable casting base, bed frame, and headstock crafted from high-strength materials, ensuring exceptional stabil...

CK52PT Power Turret Tailstock CNC Slant Bed Lathe-

CK52PT Power Turret Tailstock CNC Slant Bed Lathe

480mm maximum rotation diameter Oil pressure programmable tailstock Features a. The CK52PT CNC lathe machine features an integrated base casting and a 35° inclined bed, enhancing overall rigidity. Utilizing finite element analysis, the cast iron re...

CK46P-Y80 Power Turret 4-Axis CNC Slant Bed Lathe-

CK46P-Y80 Power Turret 4-Axis CNC Slant Bed Lathe

1. 12-station Y-axis power turret 2. Maximum rotation diameter up to 480mm Features a. CNC lathe machine features an integrated casting base with a 35° inclined bed, enhancing overall rigidity. b. Equipped with a high-precision, rigid shell-type ...

CK46S Servo Turret 2-Axis CNC Slant Bed Lathe-

CK46S Servo Turret 2-Axis CNC Slant Bed Lathe

1. Maximum bed rotation diameter up to 700mm 2. Maximum processing length up to 400mm Features a. CNC lathe machine features an integrated design with a robust casting base and a 35° inclined bed, enhancing overall rigidity. Optimized through finite...

CK46P-Y100 Power Turret 4-Axis CNC Slant Bed Lathe-

CK46P-Y100 Power Turret 4-Axis CNC Slant Bed Lathe

1. 12-station Y-axis power turret 2. Y-axis stroke up to 100mm Features a. CNC lathe machine adopts an extended flange slider with Taiwan PMI P-grade roller guides and HIWIN high-rigidity C3-grade screws. b. Equipped with a high-precision rigid s...

CK52P Linear Guide Power Turret CNC Slant Bed Lathe-

CK52P Linear Guide Power Turret CNC Slant Bed Lathe

1. Maximum bed rotation diameter up to 450-500mm 2. Spindle hole reach to 61mm Features a. CNC lathe machine features a durable casting base, bed frame, and headstock made of high-strength materials, ensuring long-term stability. b. CK52P CNC lath...

CK46B Linear Guide Rail CNC Slant Bed Lathe-

CK46B Linear Guide Rail CNC Slant Bed Lathe

1. 46 mm spindle 2. Casting base 3. 425mm maximum rotation diameter Features a. The CNC lathe machine features a durable casting base, with the bed base, frame, and headstock made from high-strength materials for stability. b. Adopt high-precisi...

CK46A Linear Guide Rail CNC Slant Bed Lathe-

CK46A Linear Guide Rail CNC Slant Bed Lathe

1. X/Z axis reach 900/300mm 2. 46mm Spindle 3. 425mm Maximum Rotation Diameter Features a. The integrated base design and 35° inclined bed enhance the rigidity of the lathe machine, ensuring the CNC lathe machine delivers superior stability and p...

CK36 Linear Guide Rail CNC Slant Bed Lathe-

CK36 Linear Guide Rail CNC Slant Bed Lathe

1. Casting Base 2. 36mm Spindle 3. 400mm Maximum Rotation Diameter Features Features a. The machine features a 35° inclined casting base, enhancing rigidity and stability for the CNC lathe machine. This robust casting base ensures the cnc lathe oper...

STDS52-46 Single Turret Dual Spindles CNC Slant Bed Lathe-

STDS52-46 Single Turret Dual Spindles CNC Slant Bed Lathe

1. Dual spindles (Main/Sub - 52/46mm) 2. Maximum processing diameter*length up to 360*550mm Features a. The CNC lathe machine (bed base, bed frame and headstock) features a durable casting base, bed frame, and headstock crafted from high-strength ma...

DS46-36 Dual Spindles Gang Type CNC Slant Bed Lathe-

DS46-36 Dual Spindles Gang Type CNC Slant Bed Lathe

1. Dual spindles (Main/Sub - 46/36mm) 2. Maximum cutting length up to 220mm Features a. The CNC lathe machine features a durable casting base, bed frame, and headstock crafted from high-strength materials, ensuring exceptional stability b. Dual s...

CK(46)52ST Servo Turret Tailstock CNC Slant Bed Lathe-

CK(46)52ST Servo Turret Tailstock CNC Slant Bed Lathe

1. Oil pressure programmable tailstock 2. Disc type processing diameter up to (400) 500mm Features a. CNC lathe machine features an integrated design with a robust casting base and a 35° inclined bed, enhancing overall rigidity. Optimized through ...

CK(46)52PT-Y Power Turret Tailstock CNC Slant Bed Lathe-

CK(46)52PT-Y Power Turret Tailstock CNC Slant Bed Lathe

1. Oil pressure programmable tailstock 2. Y-axis power turret Features a. The CNC lathe machine features an integrated design with a robust casting base and a 35° inclined bed, enhancing overall rigidity. b. Equipped with a high-precision rigid spind...

The difference between high torque with low rotational speed and low torque with high rotational speed-

The difference between high torque with low rotational speed and low torque with high rotational speed

In the machining scenarios of CNC lathes, high torque with low speed and low torque with high speed are two common working states. Their core difference stems from the proportional relationship between torque and speed, and this proportion directly d...

Installation Protection Technology for CNC Machine Tools in High-temperature and High-humidity Environments-

Installation Protection Technology for CNC Machine Tools in High-temperature and High-humidity Environments

In the field of industrial production, as precision equipment, the operational stability of CNC machine tools directly affects product quality and production efficiency. However, when faced with harsh environments of high temperature and humidity, th...

Safety Operation of CNC Machine Tools: 9 Mistakes That Must Never Be Made-

Safety Operation of CNC Machine Tools: 9 Mistakes That Must Never Be Made

In the field of CNC machine tool operation, safety always comes first. A small mistake can lead to major problems, not only endangering the safety of the operators themselves but also potentially causing damage to the expensive machine tool equipment...

Quick Diagnosis and Troubleshooting Methods for Electrical Circuit Short Circuits-

Quick Diagnosis and Troubleshooting Methods for Electrical Circuit Short Circuits

In modern manufacturing, numerical control (NC) machine tools have become core equipment on production lines due to their advantages of high precision and efficiency. However, electrical circuit short circuits—a common fault—can not only cause equipm...

What types of parts can be made on a Gang Type CNC Lathe?-

What types of parts can be made on a Gang Type CNC Lathe?

Our Gang Type CNC Lathe is a versatile machine widely used in precision machining industries. Unlike traditional lathes, it features a gang tool post that holds multiple cutting tools simultaneously, allowing for high-speed, multi-operation machini...

Unveiling 6 Gear Processing Methods: Finally Understand How Gears Are Made!-

Unveiling 6 Gear Processing Methods: Finally Understand How Gears Are Made!

As a core component in mechanical transmission systems, gears are present in almost every mechanical device we encounter in daily life. From automotive gearboxes to power tools, from clocks to industrial robots, gears are ubiquitous. Let’s uncover si...

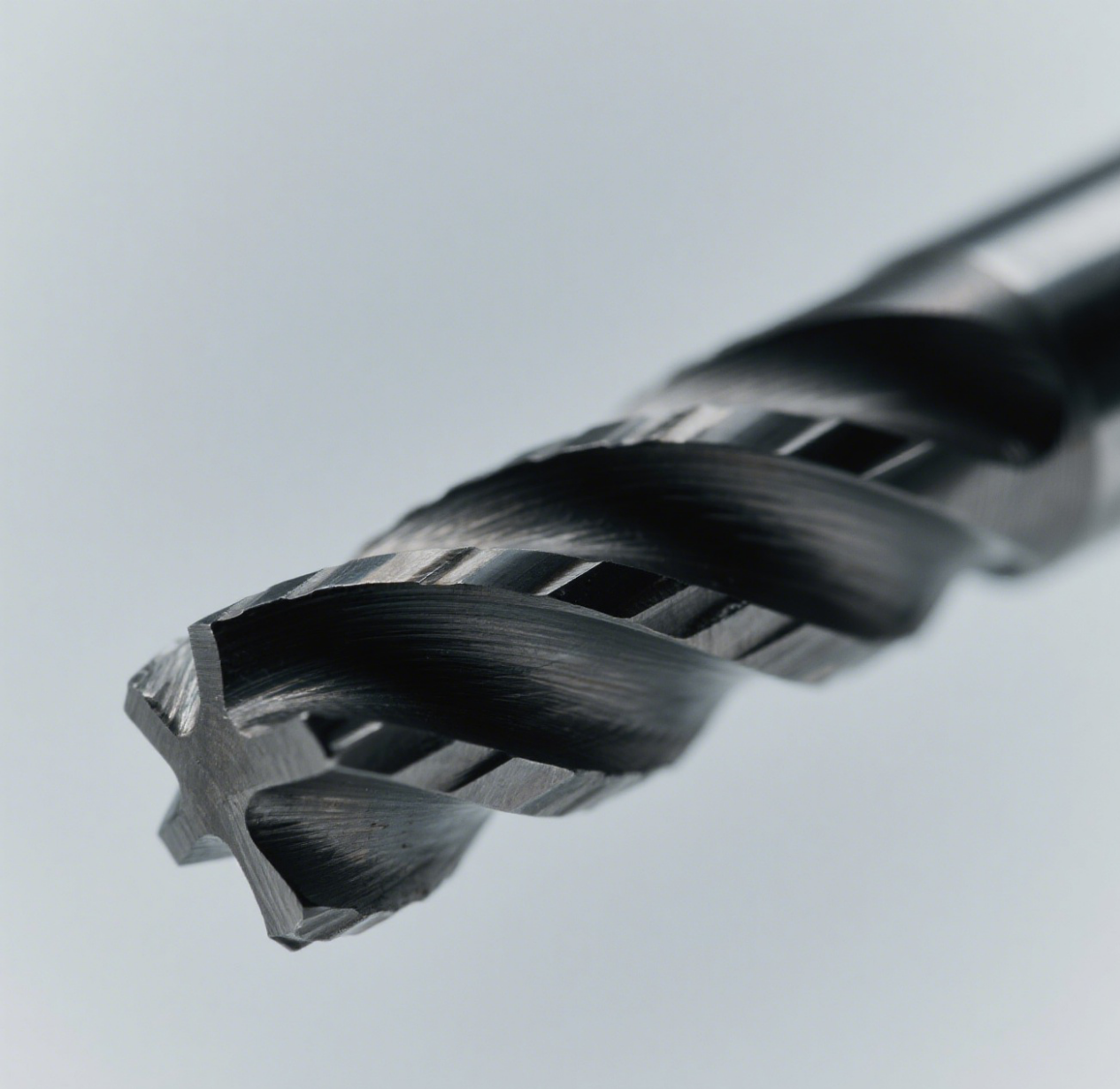

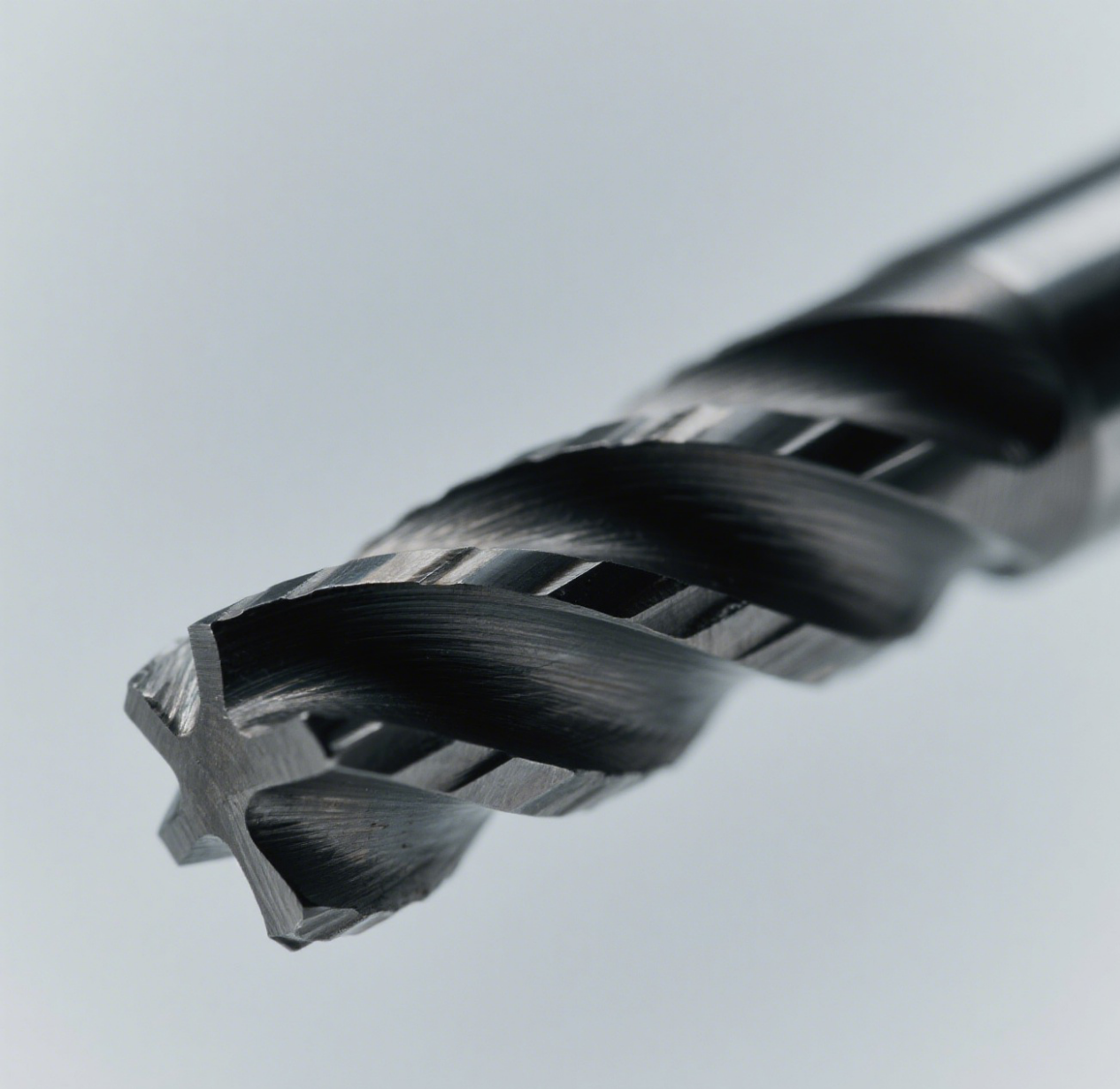

Special Tools for Composite Material Processing: The Nemesis of Carbon Fiber!-

Special Tools for Composite Material Processing: The Nemesis of Carbon Fiber!

In aerospace, new energy vehicles, high-end medical equipment and other fields, carbon fiber reinforced polymer (CFRP) has gradually become the "new favorite" of many high-end industries due to its high strength, low density, corrosion resistance and...

What is a Gang Type CNC Lathe?-

What is a Gang Type CNC Lathe?

Small-part manufacturers often struggle with high-volume turning where frequent tool changes slow production. A Gang Type CNC Lathe solves this by mounting multiple cutting tools in a linear slide (gang tool plate) instead of a rotating turret.

What is a CNC tailstock?-

What is a CNC tailstock?

CNC tailstock is the fixed-or-programmable support opposite a lathe spindle that prevents deflection, chatter and runout when turning long or slender parts.

Green CNC Machine Tools: Zero-Emission Machining Will Become an Industry Standard-

Green CNC Machine Tools: Zero-Emission Machining Will Become an Industry Standard

Against the backdrop of the global effort to address climate change and the vigorous promotion of sustainable development, the green transformation of manufacturing, a vital pillar of economic growth, has become an urgent priority. As the core equipm...

2026 Beijing International Machine Tool Show: Smart Manufacturing Leads Industry Transformation-

2026 Beijing International Machine Tool Show: Smart Manufacturing Leads Industry Transformation

The global machine tool industry is turning its attention to Beijing, where an industrial event aimed at reshaping the future of manufacturing is in the making. From May 25 to 29, 2026, the 17th China International Machine Tool Show (CIMES) will gran...

Optimization of Anti-Interference Program for Tool Collision with Workpiece During Tool Change-

Optimization of Anti-Interference Program for Tool Collision with Workpiece During Tool Change

In the process of CNC (Computer Numerical Control) lathe machining, tool change is a critical link connecting different processes. However, if a collision between the tool and the workpiece occurs during this process, it will not only cause tool dama...

Cleanliness Requirements for the Installation of CNC Machine Tools Used in Medical Device Manufacturing-

Cleanliness Requirements for the Installation of CNC Machine Tools Used in Medical Device Manufacturing

In the field of medical device manufacturing, the precision and safety of products are directly linked to patients' lives and health, brooking no oversight. As the core equipment for medical device production, the installation cleanliness of CNC mach...

What tools are used for machining stainless steel? These 5 types of inserts increase service life by 50%!-

What tools are used for machining stainless steel? These 5 types of inserts increase service life by 50%!

The issues of tool sticking, work-hardening, and difficult chip breaking when machining stainless steel have plagued countless lathe operators. Choosing a suitable insert has thus become crucial for improving efficiency and reducing costs. 1.Coated C...

What should I do if the CNC machine tool keeps alarming?-

What should I do if the CNC machine tool keeps alarming?

The frequent alarm of CNC machine tools, slight downtime affects production, and seriously damages the equipment! But many failures are actually caused by several common accessories. Today, take stock of the 7 accessories that are most likely to caus...

Hydraulic Chuck Installation Tutorial-

Hydraulic Chuck Installation Tutorial

A workman must first sharpen his tools if he is to do his work well. For the operation of a CNC lathe, the precise installation of the hydraulic chuck is the first step towards efficient machining and ensuring accuracy. 您的浏览器不支持 video 标签。 Pre-insta...

The servo matching problem of convex and concave when arc machining crosses quadrants-

The servo matching problem of convex and concave when arc machining crosses quadrants

Servo Matching Issues Causing Convex and Concave Defects When CNC Machine Tools Process Arcs Across Quadrants: In - depth Analysis from Principles to Solutions Arc machining is a fundamental yet highly technical operation. Many operators have encount...

Do you know what the standard concentration of cutting fluid for CNC machine tools is?-

Do you know what the standard concentration of cutting fluid for CNC machine tools is?

What is the standard concentration of the cutting fluid for CNC machine tools? In the machining world of CNC machine tools, the cutting fluid is like an all-around guard that safeguards the machine tool and the workpiece, and its concentration is the...

Real-shot manufacturing process of ball screw: Finally understand why it is so expensive.-

Real-shot manufacturing process of ball screw: Finally understand why it is so expensive.

The entire manufacturing process of ball screws is recorded with lenses. I was originally puzzled by the high price of this small part, but after watching the whole process, I realized that behind its value are countless strict processes and top-notc...

Why is titanium alloy a difficult-to-machine material?-

Why is titanium alloy a difficult-to-machine material?

Why do we consider titanium alloy a difficult-to-machine material? Because there is a lack of profound understanding of its machining mechanisms and phenomena. 您的浏览器不支持 video 标签。 1.Unique physical properties: processing hindrance The high strength an...

The difference between high torque with low rotational speed and low torque with high rotational speed-

The difference between high torque with low rotational speed and low torque with high rotational speed

In the machining scenarios of CNC lathes, high torque with low speed and low torque with high speed are two common working states. Their core difference stems from the proportional relationship between torque and speed, and this proportion directly d...

Installation Protection Technology for CNC Machine Tools in High-temperature and High-humidity Environments-

Installation Protection Technology for CNC Machine Tools in High-temperature and High-humidity Environments

In the field of industrial production, as precision equipment, the operational stability of CNC machine tools directly affects product quality and production efficiency. However, when faced with harsh environments of high temperature and humidity, th...

Safety Operation of CNC Machine Tools: 9 Mistakes That Must Never Be Made-

Safety Operation of CNC Machine Tools: 9 Mistakes That Must Never Be Made

In the field of CNC machine tool operation, safety always comes first. A small mistake can lead to major problems, not only endangering the safety of the operators themselves but also potentially causing damage to the expensive machine tool equipment...

Quick Diagnosis and Troubleshooting Methods for Electrical Circuit Short Circuits-

Quick Diagnosis and Troubleshooting Methods for Electrical Circuit Short Circuits

In modern manufacturing, numerical control (NC) machine tools have become core equipment on production lines due to their advantages of high precision and efficiency. However, electrical circuit short circuits—a common fault—can not only cause equipm...

What types of parts can be made on a Gang Type CNC Lathe?-

What types of parts can be made on a Gang Type CNC Lathe?

Our Gang Type CNC Lathe is a versatile machine widely used in precision machining industries. Unlike traditional lathes, it features a gang tool post that holds multiple cutting tools simultaneously, allowing for high-speed, multi-operation machini...

Unveiling 6 Gear Processing Methods: Finally Understand How Gears Are Made!-

Unveiling 6 Gear Processing Methods: Finally Understand How Gears Are Made!

As a core component in mechanical transmission systems, gears are present in almost every mechanical device we encounter in daily life. From automotive gearboxes to power tools, from clocks to industrial robots, gears are ubiquitous. Let’s uncover si...

Special Tools for Composite Material Processing: The Nemesis of Carbon Fiber!-

Special Tools for Composite Material Processing: The Nemesis of Carbon Fiber!

In aerospace, new energy vehicles, high-end medical equipment and other fields, carbon fiber reinforced polymer (CFRP) has gradually become the "new favorite" of many high-end industries due to its high strength, low density, corrosion resistance and...

What is a Gang Type CNC Lathe?-

What is a Gang Type CNC Lathe?

Small-part manufacturers often struggle with high-volume turning where frequent tool changes slow production. A Gang Type CNC Lathe solves this by mounting multiple cutting tools in a linear slide (gang tool plate) instead of a rotating turret.